In the world of milk-based coffee, texture is everything. That silky, balanced microfoam that crowns a latte or glides into a clean rosetta pattern is never an accident. It's the result of controlled heat, structured aeration, and finely tuned flow dynamics. With AeroSilk™ Technology, this level of precision comes home by combining mechanical design and intelligent automation into one coordinated frothing system.

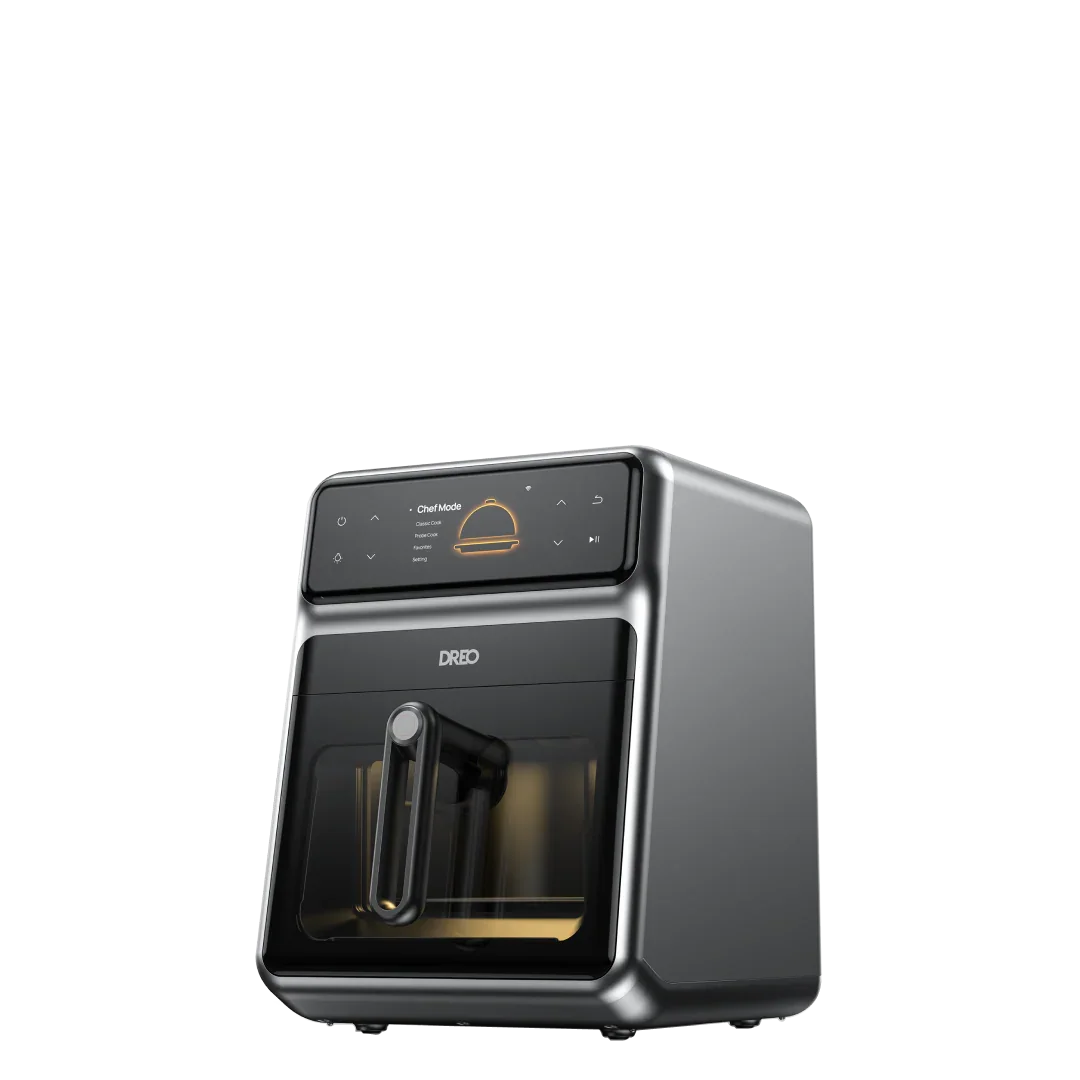

AeroSilk™ is built on three integrated pillars: advanced frothing tips, a multi-stage automated frothing program, and smart control logic that adapts to different milk types. Together, these elements within the

DREO BaristaMaker Frother create the ultra-fine microfoam that defines a world-class milk coffe.

Engineering the Foundation: Frothing Tips That Shape the Flow

The first part of AeroSilk™ is mechanical. The

DREO BaristaMaker lineup uses specialized frothing tips that guide milk movement and control bubble formation with remarkable accuracy.

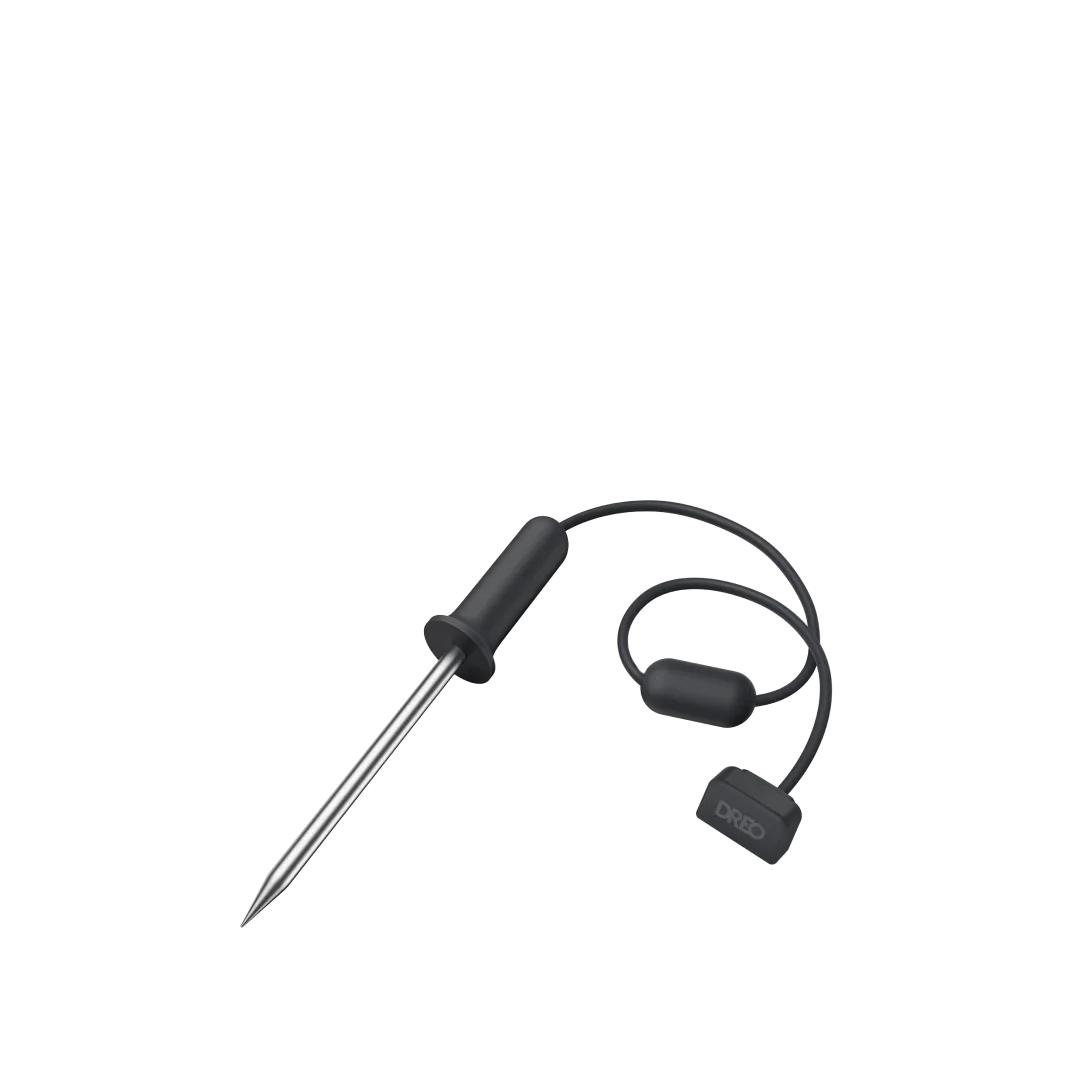

Impeller Tip: Crafted for Silky Microfoam, Ideal for Latte Art

Designed specifically for microfoam perfection, the patented Impeller Tip sits at the heart of DREO's finely tuned Barista Combo system. This advanced frothing structure blends aerodynamic shaping with thoughtful material design to achieve exceptional texture, stability, and uniformity in every cup.

Its performance comes from two key elements:

-

Centralizing Impeller Blade: Engineered to counter the natural outward pull created as milk spins, this blade inside the DREO BaristaMaker Frother Air redirects flow toward the center, focusing foam formation where it's most effective. The outcome is an even bubble structure with a smooth, crema-like finish that stays intact for latte art.

-

Micro-Level Screen: As milk moves through this ultra-fine mesh, larger air pockets are refined into dense, long-lasting microfoam with bubbles as small as 0.5 mm. The result is a lush, velvety foam with perfect elasticity for clean, precise pours.

Working together, these components convert turbulent liquid movement into organized frothing behavior - a transformation supported by fluid-flow simulations showing smoother motion and more consistent heating than traditional disc-style frothers.

Disc Tip: Smooth Results for Versatile Drinks

When a drink doesn't call for latte art density, the Disc Tip in the

DREO BaristaMaker Frother provides a gentler option. Its low-shear rotation produces foam with a lighter, softer body that suits cappuccinos, hot chocolate, and cold foam. It also blends powders effectively by breaking up clumps and dispersing ingredients evenly. The result is a smooth, consistent texture with minimal splashing.

With a magnetic, interchangeable design, switching tips is fast and intuitive. This setup flexes easily between precision microfoam and simple everyday drinks.

The Multi-Stage Frothing Program: A Barista's Workflow in Code

AeroSilk™ goes beyond hardware. Its signature microfoam comes from a multi-stage program that follows the same sequence a barista uses when steaming milk.

Stage 1: Rapid Heating

The process starts with high-efficiency thermal control. Sensors track milk temperature in real time and drive fast, precise heating to the target 149°F (65°C), while guarding against scalding. This sets the foundation by keeping the milk in the ideal zone: warm enough to unlock natural sweetness, yet stable enough to preserve foam structure.

Stage 2: Aeration

At the right temperature, the system increases rotation and begins introducing air. Rather than depending on speed alone, it synchronizes RPM with carefully timed air pulses. This coordination manages bubble size, avoids over-expansion, and maintains a balanced air-to-liquid ratio. The foam created here becomes the base for the finer microfoam that follows.

Stage 3: Microfoam Refinement

In the final phase, rotation gradually eases, and the flow is guided back toward the center. This compression step folds larger bubbles into a smoother, more uniform microfoam. Just as a barista finishes with a gentle swirl to unify texture, AeroSilk™ recreates that result through algorithmic control.

All three stages run automatically. There is no need to adjust settings, monitor progress, or time transitions.

Adaptive Performance Across Milk Types

Milk behaves differently depending on its protein, fat, and stabilizer content. Oat milk can be creamy yet low in protein. Almond milk can separate easily. Dairy milk relies heavily on protein denaturation for structure.

The

DREO BaristaMaker Frother Air accounts for these variables using an adaptive frothing algorithm. Based on the milk type selected, it adjusts temperature curves, rotation speeds, timing intervals, and aeration strength. Thousands of controlled tests informed this logic, allowing AeroSilk™ to maintain:

- stable foam

- consistent bubble size

- smooth pouring

- reliable results across batches

Whether it is oat, soy, almond, or whole dairy milk, the system tailors each stage to support the best foam structure possible.

Protecting Flavor and Structure with Anti-Scorch

Precision heating is key to great foam. Excessive heat can break down milk proteins and introduce scorched, bitter notes. AeroSilk™ uses Anti-Scorch protection to track and fine-tune heat continuously, helping prevent overheating at any point in the cycle.

This protection helps preserve:

- natural sweetness

- clean flavor

- stable foam structure

- smooth mouthfeel

By pairing controlled heating with Anti-Scorch safeguards, each drink stays balanced and clean—without unwanted bitterness.

Engineering A Perfect Milk Coffee Experience

The goal of AeroSilk™ is not to mimic a barista's hand movements. It converts the same principles into a controlled, accessible system anyone can rely on.

DREO BaristaMaker Frothers apply fluid dynamics, thermal science, and adaptive programming to create café-quality microfoam with minimal effort.

If you are exploring ways to upgrade your coffee workflow at home, the BaristaMaker family offers a precise and thoughtfully engineered frothing experience that can elevate every cup you make.