At DREO, we approach airflow as an integrated system rather than a single function. In our

tower fans, the internal air duct, often treated as an afterthought in traditional designs, has been completely reimagined. Guided by aerodynamic science and acoustic engineering, we rebuilt the duct to optimize every curve and contour. Guided by aerodynamic science and acoustic engineering, we rebuilt the duct to optimize every curve and contour. The result is airflow that travels farther, feels smoother, and sounds quieter, all while keeping energy use low. Here is how we made it happen.

1. Stabilizing Flow with an Eccentric Vortex

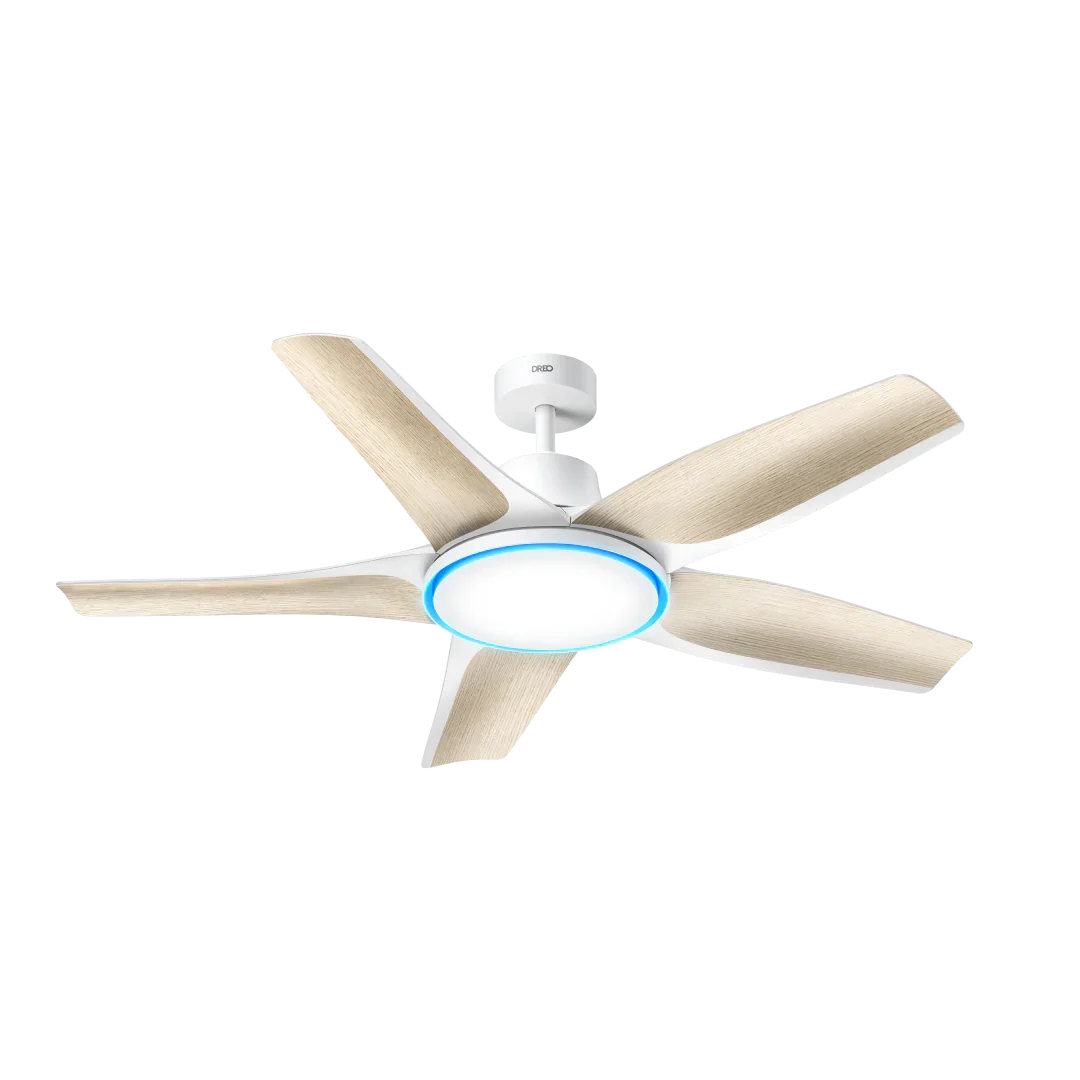

Inside most fans, airflow becomes unstable, especially near the volute, the spiral-shaped component responsible for collecting and redirecting air. In the

DREO Tower Fan Cruiser Pro T3, we addressed this by designing a subtly off-center volute tongue. This adjustment creates a controlled vortex rather than allowing random turbulence to form. The result is a more stable airflow path, better pressure recovery, and less noise caused by swirling eddies.

2. Optimizing Geometry with Bézier Curve Profiles

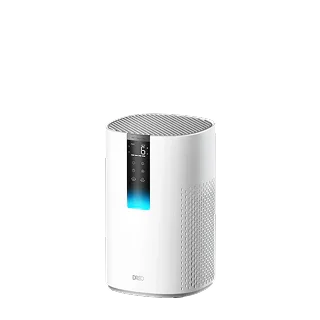

Instead of relying on simple arcs or straight lines, we shaped the inner walls of the volute in the

DREO Tower Fan Nomad One using Bézier curves. This smooth, continuous contour helps keep the airflow attached to the surface, which reduces flow separation and minimizes energy loss. It also softens abrupt changes in direction, making the entire system more acoustically stable.

3. Breaking the Pattern to Break the Noise

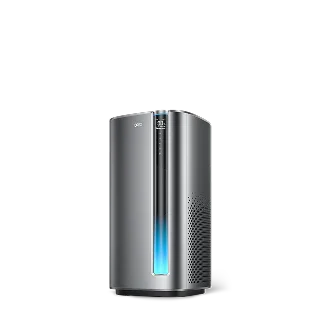

When air encounters obstacles at consistent intervals, such as the blades and the volute tongue, it generates sharp tonal noise. In the

DREO Tower Fan Pilot Max S, we addressed this by applying staggered positioning in multiple dimensions, subtly shifting the volute tongue both radially and axially. This breaks the repetitive pattern and disperses the sound spectrum, resulting in noticeably quieter performance.

4. Asymmetric Blade Spacing to Reduce Resonance

Inside the impeller, we arranged the blades at slightly irregular intervals. This breaks rotational symmetry, which is a common source of resonance and high-pitched tones. The airflow remains consistent, but the acoustic signature is softened and less intrusive.

5. Aerofoil Blades for Efficient, Quiet Airflow

We reshaped the impeller blades with a forward-cambered aerofoil profile. This curved design allows air to pass smoothly across the surface, reducing turbulence and improving efficiency. As a result, the fan delivers stronger airflow without requiring higher motor speeds.

6. Directing Air with Purpose

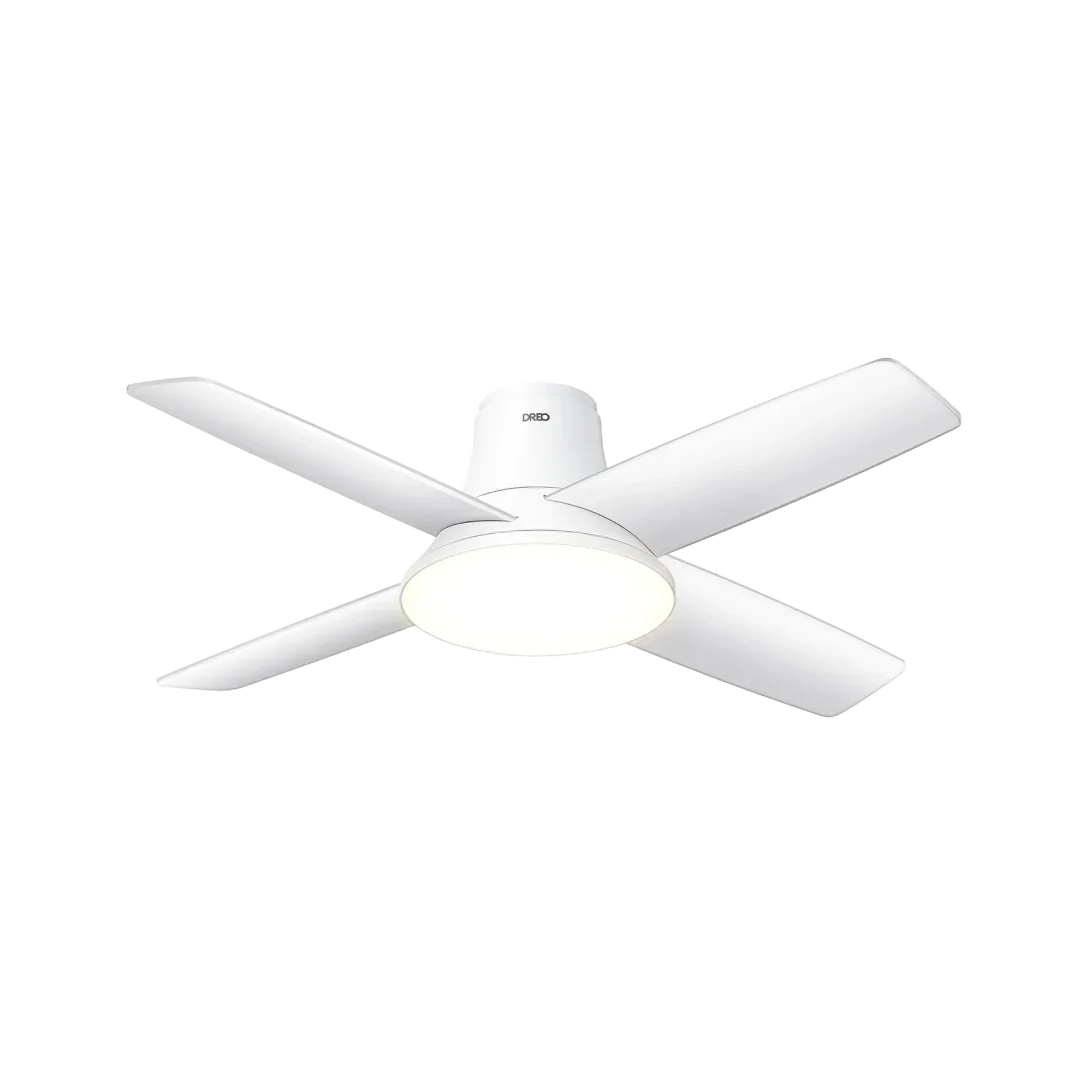

The front grille of the

DREO Tower Fan 519 is more than a design detail. Its angled guide ribs are carefully engineered to streamline the outgoing airflow, reducing resistance and increasing exit velocity. Drawing inspiration from the Coandă effect, the grille guides air along its curved surfaces, helping it stay attached and flow more cleanly. This design reduces turbulence and lowers noise levels, even at higher speeds.

7. Refined Intake for Balanced Pressure

We also redesigned the side intake duct to improve how air enters the system. A more stable intake leads to better pressure consistency before the air reaches the impeller, laying the foundation for a smoother flow throughout the entire system.

Final Takeaway

Every element—from volute geometry to the blade layout and outlet structure — was developed as part of a unified system. This holistic approach allowed DREO to strengthen airflow, minimize noise, and preserve energy efficiency without increasing the motor load.

When aerodynamics, acoustics, and thermal design come together with intention, the result goes beyond a better fan. It becomes a smarter airflow, engineered to perform quietly, efficiently, and effortlessly in your space.